Handbuilt wheels... the big thread

Comments

-

Ambrosio Excellight are lovely old school narrow box section rims. I've recently built a set of 28s and they're very nice indeed. No use for tubeless though and thoroughly unfashionable, but well suited to a classic steel frame.rnath wrote:The 32H rims on my single speed bike need replacing and I was all set on DT Swiss RR411's until my LBS informed me they only go up to 28H. I'm after a black clincher rim without anodized brake track (so not Archetype etc), for a classic steel frame - light would be good. The new Open Pro is a bit too funky looking for this bike. Pacenti Forza looks like it would be go-er - is there anything else I should be looking at? Thanks...0 -

Yes, I have some of the Excellights. They can be had in 'silver' and look really lovely on an old bike. 15mm internal width so not too bad, certainly when matched with some Vittoria G+. The only downside on mine is that the weld swarf became detached internally and now rattles when I ride under about 10mph, which is a good incentive to keep the speed up!

Mine are complete with some nice spangly Record hubs from about 20 years ago :-)0 -

OfficerDigby wrote:thecycleclinic wrote:Well Miche dropped by today and we had a chat. I visited there factory in march to discuss a BORG hub. Not some rebranded hub but something completely new as the hub I want does not exist.

As I do a lot of 24 spoke rear wheels and triplet lacing pattern (16:8) is good for tubeless tyres given a big tension drop (although I do wonder if the new Mavic OP rims addresses this issue). Triplet lacing overcomes this due to the high NDS tension to begin with. I also wont have to tension the DS spokes up to the very limit the rim can tolerate which must be helpful. However there are no triplet hubs available aftermarket that are any good. Bitex do one but it is a standard hub and the geometry is all wrong for triplet lacing. Miche used to make one but it was straight pull only.

So a custom hub forging (I have pricing now) will be manufactured. The rear hub will have 1x 6803 SKF bearing NDS and 2x 6803 or 6903 SKF bearings DS. The freehub will have 2x 6803 bearings. The axle will be borrowed from the SWR hub range. The end caps will be current SWR but Miche have a end cap design which they have never used which limits water ingress. IT was developed for a customer who wanted CX wheels but the order never materialised. The design exists though so I could simply use it.

The flanges will be standard J-bend with standard spoke holes. The flange spacing for the rear centre to middle of hub will be 17mm DS and 49mm NDS. That will give a tension balance of 70% and with an offset Kinlin rim 87% is possible.

I have successfully built with the current SWR hubs which has similar geometry but for straight pull spokes but 1:1 lacing and even though the tension balance is very low the resulting wheels are so stiff it does not matter. So maybe they can be conventially drilled as well. since 18:9 drilling can also be done but that will require special rims so will that be worth it all the extra costs.

the freehub will be reworked with 4 pawls and independent springs. Perhaps the pawls could be arranged asymmetrically to increase points of engagement without having to increase the number teeth on the ratchet ring.

Cost will be reasonable. Certainly no more than Hope's road hub costs.

The front hub will borrow alot from the current SWR hub but will be forged and have standard flanges.

I am expecting hub weight to be about 380g/pair.

In time I could actually have a hub shell for conventional drilling made. I probably will do both.

Steel free hub body,.. steel free hub body,... steel freehub body.

And OH did I say steel free hub body?

please!

And different hub colors!!

Sounds like a very interesting project, but I would like to take the oportunity to ask something. Considering how Campagnolo hubs are universally prayed, why no other brands design something similar? Is it under a patent or am I missing something?0 -

what do you mean. Plenty of manufacturers do something similar, shimano for one. Campagnolo like hubs would be quite expensive to do on a smaller scale and why when a cartridge bearing hub will be just as reliable if done right. Colours well that creates problems of its own. Anodising comes out differently batch to batch and a batch would be 100 hubs. therefore the scale of production would have to ten times what I am planning and the demand would have to be there too. one step at a time.http://www.thecycleclinic.co.uk -wheel building and other stuff.0

-

Will the drillings on the NDS flange be optimised/spaced apart for 1x lacing?thecycleclinic wrote:As I do a lot of 24 spoke rear wheels and triplet lacing pattern (16:8) is good for tubeless tyres given a big tension drop (although I do wonder if the new Mavic OP rims addresses this issue). Triplet lacing overcomes this due to the high NDS tension to begin with. I also wont have to tension the DS spokes up to the very limit the rim can tolerate which must be helpful. However there are no triplet hubs available aftermarket that are any good. Bitex do one but it is a standard hub and the geometry is all wrong for triplet lacing. Miche used to make one but it was straight pull only.

Has it ever occurred to you (or anyone in your position) to produce a hub with a short 7speed-like freehub body?thecycleclinic wrote:The flanges will be standard J-bend with standard spoke holes. The flange spacing for the rear centre to middle of hub will be 17mm DS and 49mm NDS. That will give a tension balance of 70% and with an offset Kinlin rim 87% is possible.

I ride 7speed hubs modified/spaced up to 130mm for quite a while in the pleasing knowledge that my NDS spokes are high tensioned too and not nearly slack. I have 9 sprockets out of a 10speed cassette on that freehub body (does anyone need more?).

It also gives you more options in spoke numbers to fit the range from the lightweight rider to the heavy load tourer.

btw: I second the steel freehub body.0 -

The market for 7 speed is so small it would be a loss. also a 7 seed freehub mean another forging too and another 500 rear hubs with optimised geometry for 7 speed. Can you imagine the size of the loss? I dont want to its too big.

For 2:1 lacing radial NDS is the only lacing that makes sense and they will be drilled that way. 1x could probably be done but why would you. I cannot think of a single reason why as the cross over bends are unsightly.http://www.thecycleclinic.co.uk -wheel building and other stuff.0 -

I dont second the steel freehub body. I am looking into the cost but it wont fly this I know unless it can be made cheaply and it cant as the forging and CNC costs are higher.

Also given with miche freehubs, I dont get chewed up bodies myself I have to ask why other people do. It is not the freehubs fault is what I am getting at. Also people change freehub for minor indents why when the cassette slides on and off without issue.

Steel strips on the freehub are a better solution but if the steel strips fall of and thats the risk then it will end up costing me. The steel freehub and steel strips are complicating a simple design with extra production costs or potential warranties all to avoid a problem that is avoidable in the first place. So why would I when a steel freehub wont add significant sales.

If a steel freehub add sales why dont I sell many shimano hubs or campagnolo record with steel freehub? I dont though I sell many more hubs with alloy bodies because for most this is a non issue.

90% of chewed freehubs issues can be avoided to a large extend with miche freehub by torquing the lockring to 45 Nm. the other 10% are due to the rider and only the rider can address that. The number of wheels I see with lockrings that are loose is worrying.http://www.thecycleclinic.co.uk -wheel building and other stuff.0 -

beanstalk wrote:I have 9 sprockets out of a 10speed cassette on that freehub body (does anyone need more?).

Wrong forum... here anything less than 11 speed is considered pleistocene... more luck on LFGSS left the forum March 20230

left the forum March 20230 -

thecycleclinic wrote:

Also given with miche freehubs, I dont get chewed up bodies myself I have to ask why other people do. It is not the freehubs fault is what I am getting at.

It's a fairly weak line of defence. Personally I have never been a big "indenter", but every time I had to remove a cassette there was always an element of giggling to get it out... not with the steel freehub of course, it pops out like a nice turd after a bean stew.

Was it worth the extra 100 grams or so? I think it is to be honest

But I know people who put big indentations in their freehubs and there is nothing wrong with them... your answer is that they are the problem, but that doesn't really help and neither does torquing the lockring too hard... I have seen stripped threads and they are not nice.

I think acknowledging the problem and redirecting those customers to a hub with steel freehub (being that Shimano, Hope, WI or else) is the best approachleft the forum March 20230 -

It is not a 7speed market (see my 9 sprockets).thecycleclinic wrote:The market for 7 speed is so small it would be a loss. also a 7 seed freehub mean another forging too and another 500 rear hubs with optimised geometry for 7 speed. Can you imagine the size of the loss? I dont want to its too big.

It is a market for durability, stiffness, resilience, weight reduction and everything that comes with more balanced spoke tensions.

And as far as I know you would be the only provider in the world for a 130mm hub with a short freehub body.

Why another forging?

You could take Miche's usual hubs.

You need to modify Miche's freehub body and axles and that is done by milling.

The one single reason is (for want of a better word) torque balance.thecycleclinic wrote:For 2:1 lacing radial NDS is the only lacing that makes sense and they will be drilled that way. 1x could probably be done but why would you. I cannot think of a single reason why as the cross over bends are unsightly.

Since the right flange is still not in-plane with the rim, although very close nowadays, the left flange can take it's share from the torsional load.0 -

beanstalk wrote:

It is not a 7speed market (see my 9 sprockets).thecycleclinic wrote:The market for 7 speed is so small it would be a loss. also a 7 seed freehub mean another forging too and another 500 rear hubs with optimised geometry for 7 speed. Can you imagine the size of the loss? I dont want to its too big.

It is a market for durability, stiffness, resilience, weight reduction and everything that comes with more balanced spoke tensions.

And as far as I know you would be the only provider in the world for a 130mm hub with a short freehub body.

Why another forging?

You could take Miche's usual hubs.

You need to modify Miche's freehub body and axles and that is done by milling.

The one single reason is (for want of a better word) torque balance.thecycleclinic wrote:For 2:1 lacing radial NDS is the only lacing that makes sense and they will be drilled that way. 1x could probably be done but why would you. I cannot think of a single reason why as the cross over bends are unsightly.

Since the right flange is still not in-plane with the rim, although very close nowadays, the left flange can take it's share from the torsional load.

Not meaning to sound flippant - but if you believe there is a market for these, then there is no reason to stop you commissioning Miche to make them. I'm sure Malcolm and other builders would buy them from you if they have customers that want them.0 -

Yeah, I imagine they would jump to it when a guy like me with no contacts, no business orders a 100 modified hubs.g00se wrote:Not meaning to sound flippant - but if you believe there is a market for these, then there is no reason to stop you commissioning Miche to make them.

I'm really not sure that this business works that way.g00se wrote:I'm sure Malcolm and other builders would buy them from you if they have customers that want them.0 -

The market for people wanting to buy bodged 7 speed hubs to build into hand-built wheels to run 9 speeds in 2017 is...............probably in single figures nationally.FFS! Harden up and grow a pair

0

0 -

That is why ugo I an open to the steel spline idea if it can be made reliable. There are a number of fixing methods running about in my head. I need to look into this more. The steel freehub thing is defeated by cost. but it can be offered as an "upgrade if there enough demand for one. If thousands of folk want them I will make one. The production numbers need to be big. the main issue for this is I will be sharing the freehub with miche hubs. Miche are not likely to want to use a steel freehub on there high end wheels. They use them on the very high volume low end hubs. So if my order number climb to 1000 hubs or so every year it potenitally becomes viable. Other wise I will have to order 500 to 1000 steel freehub knowing I will fit only 1/4 of that to the 500 hubs I have to order meaning I will have alot of stock of the shelf and it will break the shelf and my back and my bank balance.

So I am not saying a steel freehub wont happen but it not the first step as I can't afford it. The obvious solution to that alloy freehub notching problem that some encounter is stop using fishing gear products and move to Campagnolo. There cassette design with deeper splines solves this problem at a stroke. Given campagnolo 11 speed or miche 11 speed for campagnolo cassettes work fine with shimano 11 speed this is the obvious solution.

Step by step not all at once or nowt happens.

A Ti freehub is a possible solution. Those can be CnC machined in lower volumes. The cost would be the cost and some will pay that.

There are simple solutions to every problem but my instincts tell me the steel freehub is a non starter at this stage and simply add complexity I can do without.

Trust me beabnstalk I can tell you the call the 9 speed market is small for the wheel that I build, I sont sell many higher spoke count wheels. and many of thiose riders are on 11 speed. The issue is components. new 9 speed kit is sora level now. Why try and support a market that is now geared to entry level bikes. People who buy a £500 bike are not buying £300-£400 wheel are they. most riders now use 11 speed. Yes a new forging is required for a shorter freehub as you can widen the flange seperation. Otherwise do what you suggest and you have a pointless mod. 7 speed hubs can have wonderful tension balance making the need for 2:1 lacing redundant. those days are long gone and not coming back.

Yes I need more than 9 cogs. I have a 9 speed road bike but dont use it much as 9 speed DA kit is not that common any more.http://www.thecycleclinic.co.uk -wheel building and other stuff.0 -

thecycleclinic wrote:

So I am not saying a steel freehub wont happen but it not the first step as I can't afford it. The obvious solution to that alloy freehub notching problem that some encounter is stop using fishing gear products and move to Campagnolo.

Shame the quality of the latter has gone down a cliff over the past decade. The Record shifters I sold you are a testament of how crap these things have become. I would not touch Campagnolo with a bargepole these days.left the forum March 20230 -

Campag kit does not go wrong that often and a replacement shifter body is not expensive - £65. Try getting a dura ace shifter body for that money. In fact it may be cheaper to build a set of shfters out of Campagnolo spares than to buy a new set, Also the new 2015 shifters do have various material changes to address some of these issues. That has trickled down now to the new centaur shifters. Shimano kits goes wrong all the time. You also bought those shifter second hand (I remember the thread) and therefore you dont know how they have been treated.

Current Shimano warranty jobs are a Zee caliper (leaking) and R785 calipers leaking again yes these have been warrantied before!

So I would not be so dismissive of campag kit. My own groupsets (4 in total 2006 Record 10 speed, 2012 Veloce, 2014 Super Record RS and 2015 Record) just work.http://www.thecycleclinic.co.uk -wheel building and other stuff.0 -

I wrote I have 9 sprockets out of a 10speed cassette (CS-6700). Before that I rode Sram eTAP with 9 sprockets out of an 11speed cassette.thecycleclinic wrote:Trust me beabnstalk I can tell you the call the 9 speed market is small for the wheel that I build, I sont sell many higher spoke count wheels. and many of thiose riders are on 11 speed. The issue is components. new 9 speed kit is sora level now. Why try and support a market that is now geared to entry level bikes. People who buy a £500 bike are not buying £300-£400 wheel are they. most riders now use 11 speed.

So short freehub bodies don't prevent you from using state of the art group sets.

I wouldn't go that far, there is no need to widen the flange separation.thecycleclinic wrote:Yes a new forging is required for a shorter freehub as you can widen the flange seperation. Otherwise do what you suggest and you have a pointless mod.

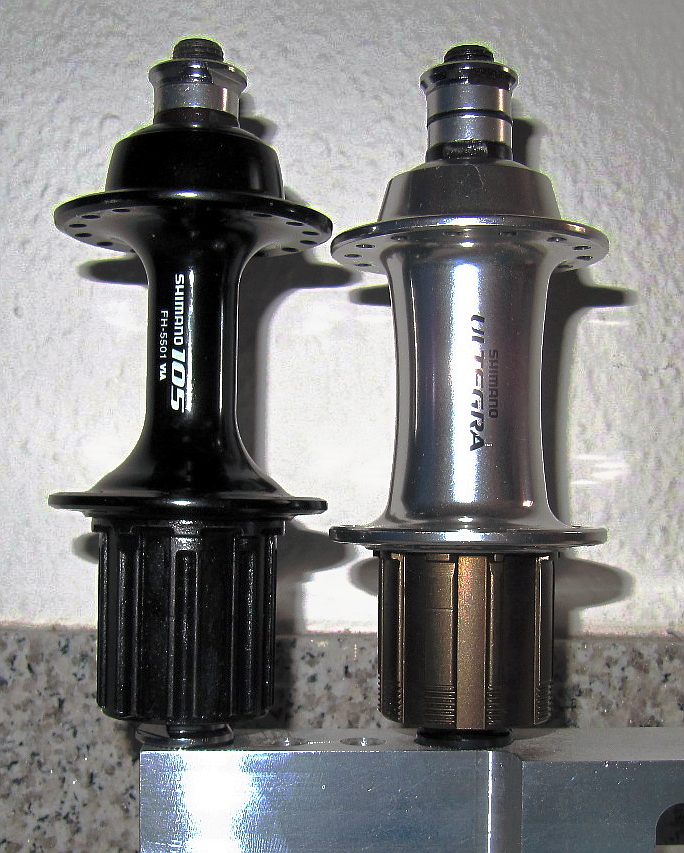

The current hub shell with both flanges as it is slides about 5mm to the right, see my hubs above.

And that really is not pointless.0 -

So I'm building some Hydra rims on Hope Pro4 hubs for my CdF, to replace the stock wheels.

Thinking about leaving the stock wheels with the gravel tyres, and the new wheels with road tyres, so I can swap based on the occasion. So 1 extra cassette and rotors need to be ordered.

The thing is, what are the chances I can just swap wheels without having to adjust again RD and brakes?

If adjustments are needed every time then probably will just keep the new wheels and swap tyres instead. Seems less of a work. In this case no cassette and rotors are needed.0 -

torino wrote:So I'm building some Hydra rims on Hope Pro4 hubs for my CdF, to replace the stock wheels.

Thinking about leaving the stock wheels with the gravel tyres, and the new wheels with road tyres, so I can swap based on the occasion. So 1 extra cassette and rotors need to be ordered.

The thing is, what are the chances I can just swap wheels without having to adjust again RD and brakes?

If adjustments are needed every time then probably will just keep the new wheels and swap tyres instead. Seems less of a work. In this case no cassette and rotors are needed.

Chances are pretty high... normally you don't need to do anything RDwise

more likely to have to adjust the rotor position for a perfect fit with the brake caliper... easier with 6bolts and sub-millimeter spacers than with centrelockleft the forum March 20230 -

Thanks I will try the spacers then. Syntace has these shims at 0.2mm thickness, should work.0

-

New Mavic OP tubless how many layers of tape do I need to apply? Thanks0

-

hazy day wrote:New Mavic OP tubless how many layers of tape do I need to apply? Thanks

twoleft the forum March 20230 -

Thank you.0

-

Questions for Malcolm. Recently taken delivery of a set of your 50mm carbon tubeless wheels which are excellent (as are the Kinlin set you built me.

The wheels when up to speed seem a bit unbalanced, as if they where out of round. I actually think this is to do with the weight of the tubeless valve. Apart from putting the speed magnet on the opposite side to the valve, is there anything else I can do to make the wheels more balanced?

Also the campag pads stop the wheels really well, much better than I anticipated, however they squeal like a little pig? Do they wear in over time?

Thanks. Alex.0 -

Have you set a bit of toe in on the pads? That helps with squeaks.Colnago Master Olympic

Colnago CLX 3.0

Colnago Dream

Giant Trinity Advanced

Italian steel winter hack0 -

Marin Maniac wrote:

The wheels when up to speed seem a bit unbalanced, as if they where out of round. I actually think this is to do with the weight of the tubeless valve.

How much sealant did you put in :?:I'm sorry you don't believe in miracles0 -

Pads should not squeel. Toe the pads in. Pad squeels can have many causes. What i do know mine dont squeel and i have not had this complaint from others.

Is tbis imbalace felt when riding or when spinnig the wheel. If its the latter ignore it. If the former then there will be a cause and a solution.

The wheels where round when they left me. Is the tyre seated properly. By that i mean is the tyre sitting low anywhere. I do look for this but i suppose i am human too. If the tyre sits low inflate until it pops into place. Maybe the tyre is not round. Weight imbalance should not be significant enough to notice. Any issues email me. Better dealt this way than on the forum.

I have never had to warranty a set of wheels for inbalance because the weight inbalace required would have to be severe.http://www.thecycleclinic.co.uk -wheel building and other stuff.0 -

Matt_N wrote:Have you set a bit of toe in on the pads? That helps with squeaks.

I've not toed them in. Never toed pads before, and never suffered from brake squeal before on all my other other ally wheels. Whats the best way to do this? I vaguely recall a credit/business card trick?SloppySchleckonds wrote:How much sealant did you put in :?:

I've not topped up the sealant since receiving them from Malcolm which about 4-weeks ago. I've probably ridden them less that 200 miles.

Malcolm - I've not noticed anything obvious with how the tyre was sitting. I'll have a closer look. The imbalance is felt both when the bike is on the work stand and on the road. I'll email you with my findings.

Thanks all for the replies. 0

0 -

You know Miche has this thing to glue on the rim to improve the balance:

https://www.youtube.com/watch?v=MGnG2qMlyYs

Idea is nice. Don't know to which extent it is really necessary.0 -

Most times I have had imbalance has been when tyre not seated correctly on the bead all the way around. Easiest way to make sure its fixed is either to over-inflate till it pops into place or if that doesnt work, mix a little washing up liquid and water in a cup and dip your fingers in and spread around the rim to make sure it doesnt stick.0