Problems with Rear Mechs

Terminology:

'mech', shortened form of mechanism or dérailleur from the French. British; 'derailleur' (no accent).

Colin's English dictionary:

noun

"a mechanism for changing gear on bicycles, consisting of a device that lifts the driving chain from one sprocket wheel to another of different size"

There are lots of things that can cause your gears to malfunction.

The following is a comprehensive guide to try and assist with the function of the rear mech specifically. I have split it up into sections so skip what you feel is not relevant to you. However, please read the initial introduction as there are some general tips to help you on your way.

You may want to cross reference any gear change problems with Ugo's FAQ post on cassette compatibility.

The anatomy of the rear mech will be come clear to you should you read this article but it is essentially comprised of a mounting bolt, 2 jockey wheels within what is called a 'cage', a frame which is a a parallelogram (explained in section 4). a pulley spring and a spring within the parallelogram and 3 adjustment screws.

1. Introduction.

2. Jockey wheels

3. Rear mech alignment

4. Worn rear mech

5. Cable mounting, cable routing

6. Levers

7. Chains

8. Electronic shifting

9. Quick indexing and set up guide

10. Final notes (and a warning)

1. Introduction.

In day's of old when men were bold... gear levers were mounted on the downtube either by an indexing/ratchet system of sorts on the lever or it was simply friction that held the lever in position. This method of gear selection is known as the 'Violin string' method. The user would become adept at positioning the lever in the right position. The position of the rear mech was entirely dependent on the user and infinitely adjustable but modern levers are fixed and the user has no method of adjustment bar the barrel adjusters at the rear mech and sometimes, on the down tube.

In those days with few gears at the back and big gaps between the cogs, transmissions were easier to maintain. As manufacturers added cogs and chains became narrower, the tolerances of the gears and the gear levers has become smaller and smaller to the point where even the most minor thing can cause the gears to not function properly.

For this reason, it is imperative that you try and keep the chain, jockey wheels and cassette as clean as you can.

The more diligent you are, the easier it is to maintain and pin point a problem should one arise.

Modern Ergo/Sti type levers deploy a dedicated mechanism similar to a ratchet, that will move the rear dérailleur a pre-determined distance: 1 cog and multiple cogs depending the type of lever.

2. Jockey wheels

Almost universally, the upper jockey wheel (the one nearest the cassette) has some amount of play in it. This is not wear. This lateral movement helps the dérailleur move the chain smoothly between cogs.

In the event that you get confused about the order of re-assembly, just make sure that you place the jockey wheels so that the one with play goes uppermost. Putting the 'fixed' jockey wheel uppermost, will cause clumsy, sticky gear changes.

Shimano pulleys have “guide pulley” written on the upper pulley and “tension pulley” written on the lower pulley. The writing should face outward when installed.

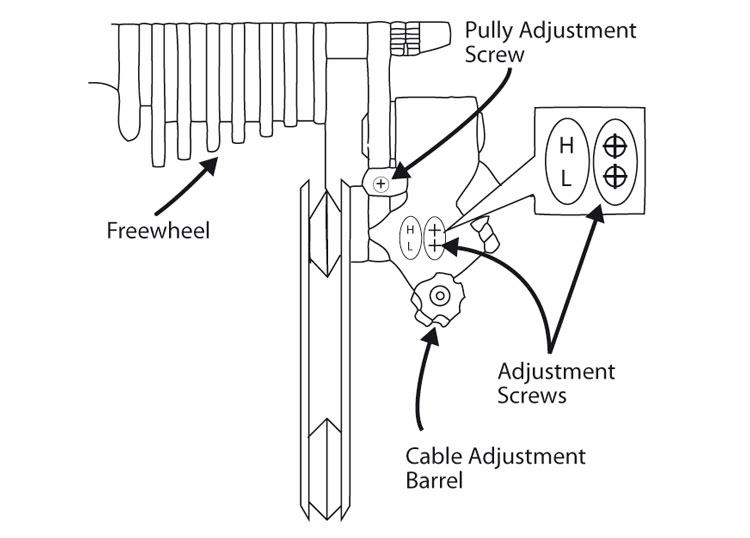

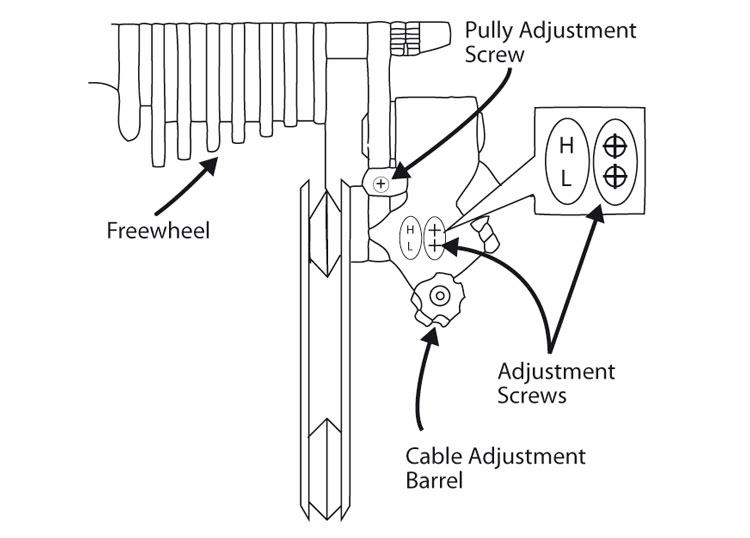

The gap between the upper jockey wheel and the cassette is an important adjustment to make for slick gear changes and varies from manufacturer to manufacturer. On the body of most rear dérailleur's is a screw which allows you to make this adjustment. This is called the 'pulley adjustment screw' or 'B-Tension screw'. This illustration is a rough guide to it's location but should not be confused with the lower (L) and upper or 'high' (H) limit screws:

In addition to the “B” screw, Campagnolo guide pulley distance adjustment uses the “H” screw (not to be confused with the upper limit screw) which works a worm drive on the jockey cage pivot.

The recommended gap between the upper jockey wheel and the cassette is surprisingly small.

Jockey wheels do wear out but replacements are easy to find.

3. Rear mech alignment

It is very easy to accidentally bend the rear mech hanger. Especially when the hanger is made from aluminium.

The usual causes: An accident, chucking it up against other bikes outside the cafe in over eager anticipation of cake, shutting your bike in the boot, someone riding in to the back of the bike etc, can all compromise the rear hanger. Thankfully, few frames nowadays have rear hangers that are part of the frame. If you think about it, It is much better that some form of contact, compromises the hanger rather than the frame itself.

So, rear hangers are often replaceable. Finding your exact one amongst the myriad of options is another thing but rest assured, they are available.

Here is a picture of a rear hanger with a single Allen key mounting bolt. Some have 2 and sometimes there are 3. The hanger bolts are also sometimes fitted on the wheel side.

Occasionally, the rear hanger mounting bolts can become loose. Make sure that the bolts are tightened to the correct torque. You do not want to damage the threads in the frame and you do not want failure of the bolts. Loose hanger bolts will cause the rear mech to move around and will affect gear changing. If the bolts come loose frequently, it is maybe an idea to use some 'thread lock' or have a competent bike mechanic to asses at the condition of the rear mech bolt hole.

Being commonly made from Aluminium and therefore, soft in comparison to the steel of the rear mech mounting bolt, it is easy to cross thread the rear mech mounting bolt when mounting the rear mech. Clean the thread thoroughly and use a little bit of grease before mounting the it. If it is cross threaded, it won't be aligned properly and you will end up having to change the hanger.

A basic tenet to check for rear mech alignment is to select the middle or nearest to middle cog in your cassette and make sure that from behind, the mech, chain and jockey wheel cage is in a straight line:

Bent rear mech hangers can be straightened and aligned with a tool, such as this Park Tool device.

Hanger alignment tool

Caution must be expressed at this point. Steel can be bent cold and undue pressure on a hanger on any frame may cause damage. If the rear hanger is excessively distorted, it may be better to replace the hanger (if it is of the replaceable kind) and if you are not confident of carrying out the process of straightening out the hanger (when it is part of the frame) yourself, take your bike to your local bike store (LBS).

4. Worn rear mech

If your rear mech has done a lot of miles, then sometimes there is play in the mechanism. Play between the sprung pivot point of the mounting bolt, where the jockey wheels are attached to the main body of the dérailleur and the pins that make up the parallelogram. The latter is simply explained: The rear mech has to move inwards whilst incrementally moving downwards in order that it does not hit the cassette. Simultaneously, the gap to any given cog and the upper jockey wheel needs to remain constant.

5. Cable mounting, cable routing

Let's look closely at the route from lever to dérailleur.

Lever entry. No matter what lever you have, it is imperative that the cable outer fits snugly into the lever. Movement of the cable at this point will cause gear changing problems. Unfortunately, to check this, it requires removal of the handlebar tape and most people will know that the tape doesn't always survive being removed so you'll just have to go out and buy some nice new tape.

Secure the cables on the bars using insulation tape at more than one point. It's a good idea to put some at the point of exit underneath the handlebar tape so that the handlebar tape itself isn't split by the cables moving during steering or transit.

Another point of entry/mounting - downtube mounts:

The above clearly shows the barrel adjusters, useful for micro adjustment of the rear mech which can be done as you ride along.

Fraying - common around the BB shell cable guide:

This is a good example of modern bottom bracket shells that are oversized, where the front mech cable goes through a small hole in the frame. It is common for dirt and debris to enter this hole and this may cause corrosion, fraying and obfuscation of the cable.

BB cable guide's are easy to obtain and when you buy a new cable kit, most brands supply a new one.

The cable at the BB cable guide receives maximum abuse as the cable goes back and forth through the guide, mixed in with dirt, salt and rain, this creates a lovely 'grinding paste' and if left to accumulate, can cause cable wear and even fraying. Do not neglect this area of the bike when cleaning.

The next entry point is on the chain stay:

...and then finally into the back of the dérailleur:

Again, there is a barrel adjuster on the rear of the dérailleur at the point of entry:

This is instrumental in assisting you to set up the rear dérailleur. Please refer to the original link in this section.

Common problem with outer cables are:

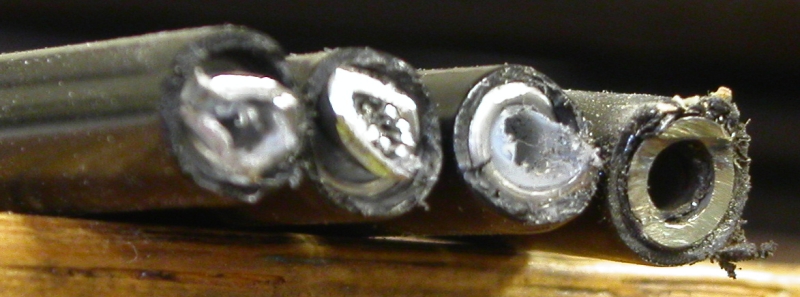

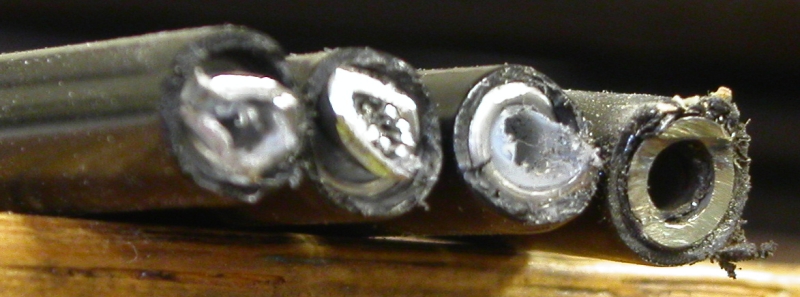

A) When the metal spiral that makes up the cable has been cut at an angle, it may produce some unwanted 'give' or movement. At the lever, this feels like the rear mech is moving but not sufficiently to change. It can feel 'spongy'. The one on the far right hand side is cut better than the first 3:

When the cable has been cut badly, it can pinch the cable causing extra friction and stiffness in gear changes.

When the cable has been cut badly, it can pinch the cable causing extra friction and stiffness in gear changes.

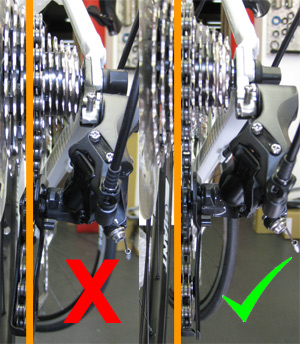

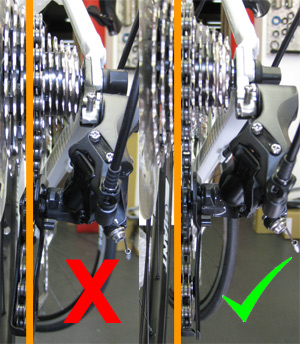

C) Too much cable from the chain stay to the rear mech and conversely, too short so that it creates a kink will result in a friction point. The cable length from chainstay to rear mech should sit in an outer that is a smooth, neat curve as in the picture of the cable going in to the Dura Ace rear mech above.

If you want to do bike maintenance, I would strongly recommend buying a dedicated cable cutter for bike cables. These cutters keep the inner and outer cable round when cutting.

A useful cutting technique is to put the inner cable into the outer, pull the inner back past the point where you are going to cut the outer and then push the inner back through once you have cut the outer. This can prevent fraying of the inner cable as you attempt to push it through the nylon sleeve and newly cut outer.

When cutting cable outers (brake or gear) it's usual to a) file the resulting cut surface until it's flat and perpendicular to the outer and b) use an appropriate sized pick or an allen key to open up the nylon lining and round out the exit hole. 1.5mm for gears and 2mm for brakes if using allen keys (in each case this is about 0.5mm thicker than the cable itself). This avoids problems with threading cable.

Internal routing of cable requires maintenance just like external routing. Water ingress, missing grommets (essential in electronic systems) can cause corrosion. It would be impossible to go through the complete variations on internal routing of cables but what I will say, is that when there is a gear change problem and you think the source is the cable, try and make sure that the cable is moving freely through the frame and the outer cables.

Some people are inclined to think that some form of lubrication is necessary with cables, either internally or externally but any lubrication will only serve to reduce corrosion as most cable outers have an internal nylon sleeve, The sleeve assists in reducing the friction of the inner cable as it moves back and forward and also reduces dirt and water ingress.

However, personally, I have used Silicone spray. Silicone spray seems to be rarely mentioned when talking about bike maintenance and does have a degree of water repellency. Be very careful not to get it on braking surfaces or brake pads. Use it sparingly.

Things to note; cables tend to be pre-stretched in the upper end of the market. Cheap one's are a bit of a lottery. If there is cable stretch, the symptom tends to be that the rear mech wants to go down a gear or you cannot get into 1st without it jumping down 1 cog or that you find that you are having to micro adjust the tension of the gear cable so that the gears run smoothly. Do not pre suppose that your fancy £25 brake cable and gear set from Shimano, Campagnolo or SRAM won't or will never stretch.

Commonly, cables can fray at the point it enters the rear cable outer on the chainstay to the rear mech. This is caused by the dual action of flexing every time you change gear and dirt/water ingress. When installing new cables, some manufacturers supply an outer cable end dedicated to fitting in to the chainstay nipple. Be careful not to dismiss this cable end and chuck in the spare parts box.

Take note of the cable ends that fit the gear cable outers and the brake cable outers - they are a different size; the brake cable outers are a bigger size than the gear cables.

Cable ends fit snugly over the cable outer and will help reduce ingress and will reduce the flex of the cable at the various mounting points (downtube, BB cable guide, chainstay nipple) and will help to facilitate smoother gear changes.

6. Levers

Levers can wear. The ratchet systems can become worn and the signs are stiffness at the lever or a vague gear change. Another symptom in severe cases is when you click up a gear, the chain jumps back down.

You can peel the hood back and use a torch to inspect the lever. Look for tiny fragments of metal and uncharacteristic wear. Eliminate all other possible problems from the cable to each mech before delving into the possibility that your levers are worn.

Make sure the cable isn't worn or frayed internally. Sometimes, this can occur at the nipple that locates the cable in the gear lever and it is difficult to spot.

7. Chains

Something to note: Some chains are uni-directional. In other words, you have to fit the chain following the manufacturers instructions and it is directionally dependent.

Wear: you can buy a wear indicator. Chains have not changed in length for a long time, so no matter what chain you have: 7, 8, 9, 10 or 11 speed, the difference is the width, not the length of link.

How to know when it's time to replace your bicycle chain

If you are not using a Quick link for chain installation, be careful not to push the link pin too far in wards. It is less critical on the chain stay side than the wheel side as a protruding link will catch on the next cog up.

http://www.bikeradar.com/gear/article/how-to-adjust-the-gears-on-your-bike-video-23582/

8. Electronic shifting

The nice thing about electronic shifting it is fairly simple. Problem can be mechanical, electrical or software.

Shimano

First mechanical. Both the front and rear mechs have limit screws. If these are mal-adjusted, chain derailment or lack of access to particular cogs is likely. The limit screws on the Shimano front dérailleurs are marked high and low and are adjusted with a 2mm Allen key. The same is true on Shimano rear dérailleurs.

If your rear gears are noisy and the top jockey wheel looks out of alignment then press the button under junction box A until the red light illuminates. Use the paddle shift button to move the rear dérailleur in small steps

Do this in the 5th gear with the limit stops properly set and then switch back to normal shifting by pressing the button till the green light appears on the junction box, then test the shifting.

Like all electrical systems there has to be power to the components for it to all work. For Shimano external batteries, if the battery will not charge fully after 1.5hrs replace it. For internal batteries if full charge is not possible after 4hrs replace it.

Connections of the various cables can also be the cause of various problems such as intermittent shifting so can firm ware faults.

Intermittent shifting can be due corroded contacts in the cable plugs or a damaged cables. The cables should be inspected and replaced if this is the case.

If you have the external battery and you have an electrical fault you need to connect via the sm-pce1 or if you have the internal battery you connect via the charger to your pc. If you have the wireless junction box you can use the e tube project software on a blue-tooth enabled device. This way faulty components can be identified.

Campagnolo

The EPS system is quite different from Shimano’s. Unlike Shimano’s Di2 system with the shifting control distributed throughout the system Campagnolo have dumb shifters and dérailleurs. Pressing a mode button on the shifters or resetting the system with a magnet are two easy ways of rectifying a fault. If that does not work with V1 and V2 fault finding was fairly basic and used a series of coloured LED's combined with a buzzer on the Campagnolo’s equivalent of the junction box under the stem to indicate where the fault lies. With wireless V3 the same fault finding system exists but in addition there is the 'my campy app' which does a similar thing.

There’s a good deal more one could say about electronic (including eTap) but Shimano also post very comprehensive service instructions to their website which include details on installation, maintenance and complete disassembly/re-assembly.

http://si.shimano.com/#/en/search/Serie ... &type=ROAD for Di2

9. Quick indexing and set up guide

i. Start with both the rear mech and down tube (if you have one) barrel adjusters. Give yourself the full leeway of adjustment and put them 2 to 3 turns from fully inserted.

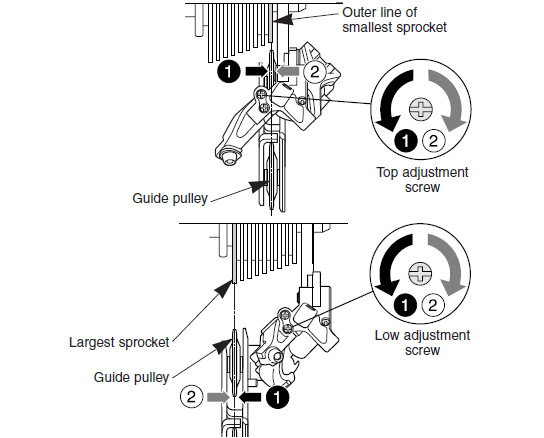

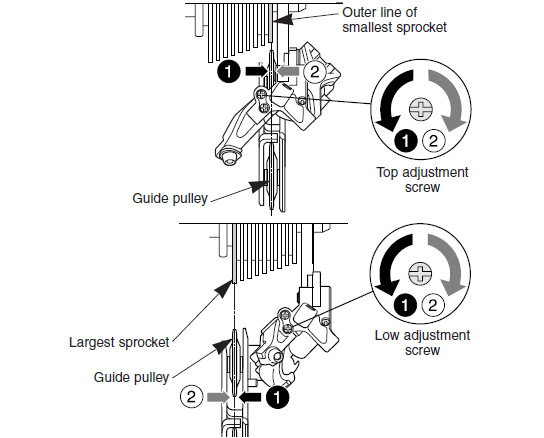

ii. Then set the L (Low limit) screw so that the gear is running relatively smoothly on the smallest cog and simultaneously, make sure that the lever is clicked all the way down. It's best to do this with cable tension on the lever. Try not to do this when the lever has no pull on it from the spring in the dérailleur mechanism.

iii. Next. Try to get sufficient tension on the cable when you clamp it so that the lever pushes the mech from the smallest cog on your cassette up 1 with one click. If it goes to the second cog but its still sketchy (most likely), then don't worry; at least you know then that the cable tension is okay.

iv. Next step is to click up to the middle of the cassette (approximate on 10 speeds) and then get it to run smoothly using the barrel adjusters. Don't rely on them to get the correct cable tension, just use them for micro adjustment so that the gear you are in is running smoothly. 95% of the cable tension should be from clamping the cable in the first place.

v. Do not attempt to flick up and down the gears at this point. First is to set the H (High limit) screw so that the dérailleur does not push the chain over the cassette towards the spokes. Chances are that the manufacturer has set he screw in deeply but do not count on this.

Click up to second biggest cog (2nd gear) and then click into first. Do not use the multiple gear function most mechanical levers have. Then try to click it into first. Make sure the limit screw isn't preventing you form selecting 1st.

If you have set the gear to run smoothly in step 4 and as long as you have clicked the correct number of clicks to get to that point in the middle of the cassette, the indexing should be fine for the whole cassette.

Trim the excess cable, add a 'cable end' for neatness and prevention of fraying the cable. Cable ends are a plus on the front mech where the end of the cable can catch on clothing. At the point it exits the clamp, you can bend the cable so that it is not pointing towards the tyre or your 7 grand Assos bib tights.

The only thing to note is what is called 'the crossover'. Although you may have 9, or 10 or 11 cogs on the cassette giving you 18, 20 and 22 gears respectively, you only really have a practical number of gears which will be less than the theoretical total.

Why? Well, because if you have the chain in 1st gear and on the big chainring, you'll find that the transmission is rather noisy and probably rubbing on the front mech. You'll also find that this is the same for 1st, 2nd, 3rd and maybe 4th -

especially with a new chain.

The converse is the same, i.e, if you have the chain on the smallest cog on your cassette and in the small chainring, there's a similar lack of smoothness. This point either way is called 'the crossover'.

What is happening is that the chain is kinked between the cassette and the chainset. It's not really designed to bend this much and spending too much time pedalling in the crossover will a) wear out bits quicker than you really want and b) is unnecessary given that there is a big overlap between gears:

http://www.bikecalc.com/gear_ratios

10. Final notes (and a warning)

Firstly, if you get a shiny new rear mech/rear dérailleur, don't chuck the instalment instructions out - there's a lot of useful stuff in the leaflet. Failing that, if you bought the bike complete or second hand, there's no shortage of information put out by the manufacturers.

Please remember to adjust the high and low screws before testing the operation of the rear mech even after the most seemingly innocuous fettling.

A chain that gets pushed over the largest cog on the cassette towards the wheel can have a catastrophic effect:

Broken spokes, a mangled rear mech, a locked up rear wheel. If you don't suffer an injury, you will be looking at a potentially hefty bill.

My thanks to: 'thecycleclinic' for compiling this article.

'mech', shortened form of mechanism or dérailleur from the French. British; 'derailleur' (no accent).

Colin's English dictionary:

noun

"a mechanism for changing gear on bicycles, consisting of a device that lifts the driving chain from one sprocket wheel to another of different size"

There are lots of things that can cause your gears to malfunction.

The following is a comprehensive guide to try and assist with the function of the rear mech specifically. I have split it up into sections so skip what you feel is not relevant to you. However, please read the initial introduction as there are some general tips to help you on your way.

You may want to cross reference any gear change problems with Ugo's FAQ post on cassette compatibility.

The anatomy of the rear mech will be come clear to you should you read this article but it is essentially comprised of a mounting bolt, 2 jockey wheels within what is called a 'cage', a frame which is a a parallelogram (explained in section 4). a pulley spring and a spring within the parallelogram and 3 adjustment screws.

1. Introduction.

2. Jockey wheels

3. Rear mech alignment

4. Worn rear mech

5. Cable mounting, cable routing

6. Levers

7. Chains

8. Electronic shifting

9. Quick indexing and set up guide

10. Final notes (and a warning)

1. Introduction.

In day's of old when men were bold... gear levers were mounted on the downtube either by an indexing/ratchet system of sorts on the lever or it was simply friction that held the lever in position. This method of gear selection is known as the 'Violin string' method. The user would become adept at positioning the lever in the right position. The position of the rear mech was entirely dependent on the user and infinitely adjustable but modern levers are fixed and the user has no method of adjustment bar the barrel adjusters at the rear mech and sometimes, on the down tube.

In those days with few gears at the back and big gaps between the cogs, transmissions were easier to maintain. As manufacturers added cogs and chains became narrower, the tolerances of the gears and the gear levers has become smaller and smaller to the point where even the most minor thing can cause the gears to not function properly.

For this reason, it is imperative that you try and keep the chain, jockey wheels and cassette as clean as you can.

The more diligent you are, the easier it is to maintain and pin point a problem should one arise.

Modern Ergo/Sti type levers deploy a dedicated mechanism similar to a ratchet, that will move the rear dérailleur a pre-determined distance: 1 cog and multiple cogs depending the type of lever.

2. Jockey wheels

Almost universally, the upper jockey wheel (the one nearest the cassette) has some amount of play in it. This is not wear. This lateral movement helps the dérailleur move the chain smoothly between cogs.

In the event that you get confused about the order of re-assembly, just make sure that you place the jockey wheels so that the one with play goes uppermost. Putting the 'fixed' jockey wheel uppermost, will cause clumsy, sticky gear changes.

Shimano pulleys have “guide pulley” written on the upper pulley and “tension pulley” written on the lower pulley. The writing should face outward when installed.

The gap between the upper jockey wheel and the cassette is an important adjustment to make for slick gear changes and varies from manufacturer to manufacturer. On the body of most rear dérailleur's is a screw which allows you to make this adjustment. This is called the 'pulley adjustment screw' or 'B-Tension screw'. This illustration is a rough guide to it's location but should not be confused with the lower (L) and upper or 'high' (H) limit screws:

In addition to the “B” screw, Campagnolo guide pulley distance adjustment uses the “H” screw (not to be confused with the upper limit screw) which works a worm drive on the jockey cage pivot.

The recommended gap between the upper jockey wheel and the cassette is surprisingly small.

Jockey wheels do wear out but replacements are easy to find.

3. Rear mech alignment

It is very easy to accidentally bend the rear mech hanger. Especially when the hanger is made from aluminium.

The usual causes: An accident, chucking it up against other bikes outside the cafe in over eager anticipation of cake, shutting your bike in the boot, someone riding in to the back of the bike etc, can all compromise the rear hanger. Thankfully, few frames nowadays have rear hangers that are part of the frame. If you think about it, It is much better that some form of contact, compromises the hanger rather than the frame itself.

So, rear hangers are often replaceable. Finding your exact one amongst the myriad of options is another thing but rest assured, they are available.

Here is a picture of a rear hanger with a single Allen key mounting bolt. Some have 2 and sometimes there are 3. The hanger bolts are also sometimes fitted on the wheel side.

Occasionally, the rear hanger mounting bolts can become loose. Make sure that the bolts are tightened to the correct torque. You do not want to damage the threads in the frame and you do not want failure of the bolts. Loose hanger bolts will cause the rear mech to move around and will affect gear changing. If the bolts come loose frequently, it is maybe an idea to use some 'thread lock' or have a competent bike mechanic to asses at the condition of the rear mech bolt hole.

Being commonly made from Aluminium and therefore, soft in comparison to the steel of the rear mech mounting bolt, it is easy to cross thread the rear mech mounting bolt when mounting the rear mech. Clean the thread thoroughly and use a little bit of grease before mounting the it. If it is cross threaded, it won't be aligned properly and you will end up having to change the hanger.

A basic tenet to check for rear mech alignment is to select the middle or nearest to middle cog in your cassette and make sure that from behind, the mech, chain and jockey wheel cage is in a straight line:

Bent rear mech hangers can be straightened and aligned with a tool, such as this Park Tool device.

Hanger alignment tool

Caution must be expressed at this point. Steel can be bent cold and undue pressure on a hanger on any frame may cause damage. If the rear hanger is excessively distorted, it may be better to replace the hanger (if it is of the replaceable kind) and if you are not confident of carrying out the process of straightening out the hanger (when it is part of the frame) yourself, take your bike to your local bike store (LBS).

4. Worn rear mech

If your rear mech has done a lot of miles, then sometimes there is play in the mechanism. Play between the sprung pivot point of the mounting bolt, where the jockey wheels are attached to the main body of the dérailleur and the pins that make up the parallelogram. The latter is simply explained: The rear mech has to move inwards whilst incrementally moving downwards in order that it does not hit the cassette. Simultaneously, the gap to any given cog and the upper jockey wheel needs to remain constant.

5. Cable mounting, cable routing

Let's look closely at the route from lever to dérailleur.

Lever entry. No matter what lever you have, it is imperative that the cable outer fits snugly into the lever. Movement of the cable at this point will cause gear changing problems. Unfortunately, to check this, it requires removal of the handlebar tape and most people will know that the tape doesn't always survive being removed so you'll just have to go out and buy some nice new tape.

Secure the cables on the bars using insulation tape at more than one point. It's a good idea to put some at the point of exit underneath the handlebar tape so that the handlebar tape itself isn't split by the cables moving during steering or transit.

Another point of entry/mounting - downtube mounts:

The above clearly shows the barrel adjusters, useful for micro adjustment of the rear mech which can be done as you ride along.

Fraying - common around the BB shell cable guide:

This is a good example of modern bottom bracket shells that are oversized, where the front mech cable goes through a small hole in the frame. It is common for dirt and debris to enter this hole and this may cause corrosion, fraying and obfuscation of the cable.

BB cable guide's are easy to obtain and when you buy a new cable kit, most brands supply a new one.

The cable at the BB cable guide receives maximum abuse as the cable goes back and forth through the guide, mixed in with dirt, salt and rain, this creates a lovely 'grinding paste' and if left to accumulate, can cause cable wear and even fraying. Do not neglect this area of the bike when cleaning.

The next entry point is on the chain stay:

...and then finally into the back of the dérailleur:

Again, there is a barrel adjuster on the rear of the dérailleur at the point of entry:

This is instrumental in assisting you to set up the rear dérailleur. Please refer to the original link in this section.

Common problem with outer cables are:

A) When the metal spiral that makes up the cable has been cut at an angle, it may produce some unwanted 'give' or movement. At the lever, this feels like the rear mech is moving but not sufficiently to change. It can feel 'spongy'. The one on the far right hand side is cut better than the first 3:

C) Too much cable from the chain stay to the rear mech and conversely, too short so that it creates a kink will result in a friction point. The cable length from chainstay to rear mech should sit in an outer that is a smooth, neat curve as in the picture of the cable going in to the Dura Ace rear mech above.

If you want to do bike maintenance, I would strongly recommend buying a dedicated cable cutter for bike cables. These cutters keep the inner and outer cable round when cutting.

A useful cutting technique is to put the inner cable into the outer, pull the inner back past the point where you are going to cut the outer and then push the inner back through once you have cut the outer. This can prevent fraying of the inner cable as you attempt to push it through the nylon sleeve and newly cut outer.

When cutting cable outers (brake or gear) it's usual to a) file the resulting cut surface until it's flat and perpendicular to the outer and b) use an appropriate sized pick or an allen key to open up the nylon lining and round out the exit hole. 1.5mm for gears and 2mm for brakes if using allen keys (in each case this is about 0.5mm thicker than the cable itself). This avoids problems with threading cable.

Internal routing of cable requires maintenance just like external routing. Water ingress, missing grommets (essential in electronic systems) can cause corrosion. It would be impossible to go through the complete variations on internal routing of cables but what I will say, is that when there is a gear change problem and you think the source is the cable, try and make sure that the cable is moving freely through the frame and the outer cables.

Some people are inclined to think that some form of lubrication is necessary with cables, either internally or externally but any lubrication will only serve to reduce corrosion as most cable outers have an internal nylon sleeve, The sleeve assists in reducing the friction of the inner cable as it moves back and forward and also reduces dirt and water ingress.

However, personally, I have used Silicone spray. Silicone spray seems to be rarely mentioned when talking about bike maintenance and does have a degree of water repellency. Be very careful not to get it on braking surfaces or brake pads. Use it sparingly.

Things to note; cables tend to be pre-stretched in the upper end of the market. Cheap one's are a bit of a lottery. If there is cable stretch, the symptom tends to be that the rear mech wants to go down a gear or you cannot get into 1st without it jumping down 1 cog or that you find that you are having to micro adjust the tension of the gear cable so that the gears run smoothly. Do not pre suppose that your fancy £25 brake cable and gear set from Shimano, Campagnolo or SRAM won't or will never stretch.

Commonly, cables can fray at the point it enters the rear cable outer on the chainstay to the rear mech. This is caused by the dual action of flexing every time you change gear and dirt/water ingress. When installing new cables, some manufacturers supply an outer cable end dedicated to fitting in to the chainstay nipple. Be careful not to dismiss this cable end and chuck in the spare parts box.

Take note of the cable ends that fit the gear cable outers and the brake cable outers - they are a different size; the brake cable outers are a bigger size than the gear cables.

Cable ends fit snugly over the cable outer and will help reduce ingress and will reduce the flex of the cable at the various mounting points (downtube, BB cable guide, chainstay nipple) and will help to facilitate smoother gear changes.

6. Levers

Levers can wear. The ratchet systems can become worn and the signs are stiffness at the lever or a vague gear change. Another symptom in severe cases is when you click up a gear, the chain jumps back down.

You can peel the hood back and use a torch to inspect the lever. Look for tiny fragments of metal and uncharacteristic wear. Eliminate all other possible problems from the cable to each mech before delving into the possibility that your levers are worn.

Make sure the cable isn't worn or frayed internally. Sometimes, this can occur at the nipple that locates the cable in the gear lever and it is difficult to spot.

7. Chains

Something to note: Some chains are uni-directional. In other words, you have to fit the chain following the manufacturers instructions and it is directionally dependent.

Wear: you can buy a wear indicator. Chains have not changed in length for a long time, so no matter what chain you have: 7, 8, 9, 10 or 11 speed, the difference is the width, not the length of link.

How to know when it's time to replace your bicycle chain

If you are not using a Quick link for chain installation, be careful not to push the link pin too far in wards. It is less critical on the chain stay side than the wheel side as a protruding link will catch on the next cog up.

http://www.bikeradar.com/gear/article/how-to-adjust-the-gears-on-your-bike-video-23582/

8. Electronic shifting

The nice thing about electronic shifting it is fairly simple. Problem can be mechanical, electrical or software.

Shimano

First mechanical. Both the front and rear mechs have limit screws. If these are mal-adjusted, chain derailment or lack of access to particular cogs is likely. The limit screws on the Shimano front dérailleurs are marked high and low and are adjusted with a 2mm Allen key. The same is true on Shimano rear dérailleurs.

If your rear gears are noisy and the top jockey wheel looks out of alignment then press the button under junction box A until the red light illuminates. Use the paddle shift button to move the rear dérailleur in small steps

Do this in the 5th gear with the limit stops properly set and then switch back to normal shifting by pressing the button till the green light appears on the junction box, then test the shifting.

Like all electrical systems there has to be power to the components for it to all work. For Shimano external batteries, if the battery will not charge fully after 1.5hrs replace it. For internal batteries if full charge is not possible after 4hrs replace it.

Connections of the various cables can also be the cause of various problems such as intermittent shifting so can firm ware faults.

Intermittent shifting can be due corroded contacts in the cable plugs or a damaged cables. The cables should be inspected and replaced if this is the case.

If you have the external battery and you have an electrical fault you need to connect via the sm-pce1 or if you have the internal battery you connect via the charger to your pc. If you have the wireless junction box you can use the e tube project software on a blue-tooth enabled device. This way faulty components can be identified.

Campagnolo

The EPS system is quite different from Shimano’s. Unlike Shimano’s Di2 system with the shifting control distributed throughout the system Campagnolo have dumb shifters and dérailleurs. Pressing a mode button on the shifters or resetting the system with a magnet are two easy ways of rectifying a fault. If that does not work with V1 and V2 fault finding was fairly basic and used a series of coloured LED's combined with a buzzer on the Campagnolo’s equivalent of the junction box under the stem to indicate where the fault lies. With wireless V3 the same fault finding system exists but in addition there is the 'my campy app' which does a similar thing.

There’s a good deal more one could say about electronic (including eTap) but Shimano also post very comprehensive service instructions to their website which include details on installation, maintenance and complete disassembly/re-assembly.

http://si.shimano.com/#/en/search/Serie ... &type=ROAD for Di2

9. Quick indexing and set up guide

i. Start with both the rear mech and down tube (if you have one) barrel adjusters. Give yourself the full leeway of adjustment and put them 2 to 3 turns from fully inserted.

ii. Then set the L (Low limit) screw so that the gear is running relatively smoothly on the smallest cog and simultaneously, make sure that the lever is clicked all the way down. It's best to do this with cable tension on the lever. Try not to do this when the lever has no pull on it from the spring in the dérailleur mechanism.

iii. Next. Try to get sufficient tension on the cable when you clamp it so that the lever pushes the mech from the smallest cog on your cassette up 1 with one click. If it goes to the second cog but its still sketchy (most likely), then don't worry; at least you know then that the cable tension is okay.

iv. Next step is to click up to the middle of the cassette (approximate on 10 speeds) and then get it to run smoothly using the barrel adjusters. Don't rely on them to get the correct cable tension, just use them for micro adjustment so that the gear you are in is running smoothly. 95% of the cable tension should be from clamping the cable in the first place.

v. Do not attempt to flick up and down the gears at this point. First is to set the H (High limit) screw so that the dérailleur does not push the chain over the cassette towards the spokes. Chances are that the manufacturer has set he screw in deeply but do not count on this.

Click up to second biggest cog (2nd gear) and then click into first. Do not use the multiple gear function most mechanical levers have. Then try to click it into first. Make sure the limit screw isn't preventing you form selecting 1st.

If you have set the gear to run smoothly in step 4 and as long as you have clicked the correct number of clicks to get to that point in the middle of the cassette, the indexing should be fine for the whole cassette.

Trim the excess cable, add a 'cable end' for neatness and prevention of fraying the cable. Cable ends are a plus on the front mech where the end of the cable can catch on clothing. At the point it exits the clamp, you can bend the cable so that it is not pointing towards the tyre or your 7 grand Assos bib tights.

The only thing to note is what is called 'the crossover'. Although you may have 9, or 10 or 11 cogs on the cassette giving you 18, 20 and 22 gears respectively, you only really have a practical number of gears which will be less than the theoretical total.

Why? Well, because if you have the chain in 1st gear and on the big chainring, you'll find that the transmission is rather noisy and probably rubbing on the front mech. You'll also find that this is the same for 1st, 2nd, 3rd and maybe 4th -

especially with a new chain.

The converse is the same, i.e, if you have the chain on the smallest cog on your cassette and in the small chainring, there's a similar lack of smoothness. This point either way is called 'the crossover'.

What is happening is that the chain is kinked between the cassette and the chainset. It's not really designed to bend this much and spending too much time pedalling in the crossover will a) wear out bits quicker than you really want and b) is unnecessary given that there is a big overlap between gears:

http://www.bikecalc.com/gear_ratios

10. Final notes (and a warning)

Firstly, if you get a shiny new rear mech/rear dérailleur, don't chuck the instalment instructions out - there's a lot of useful stuff in the leaflet. Failing that, if you bought the bike complete or second hand, there's no shortage of information put out by the manufacturers.

Please remember to adjust the high and low screws before testing the operation of the rear mech even after the most seemingly innocuous fettling.

A chain that gets pushed over the largest cog on the cassette towards the wheel can have a catastrophic effect:

Broken spokes, a mangled rear mech, a locked up rear wheel. If you don't suffer an injury, you will be looking at a potentially hefty bill.

My thanks to: 'thecycleclinic' for compiling this article.

seanoconn - gruagach craic!

1

Comments

-

If the plan is to make this a sticky, then please edit the title to remove the apostrophe?0

-

Very useful article, thanks for taking the time to do this. One suggestion, where you refer to the pulley adjustment screw, may be useful to put in brackets (B-Tension screw).0

-

Last of all, changing the Bottom Bracket to a different type can change the 'chain line' and may require some adjustment of the rear and front mech.

This should be clarified, I think. It may be true of some square tapers, but most external or press-fit BBs these days will not have this issue. Chain line is not really a critical factor on multi-speed transmissions in any case.0 -

No.8 No SRAM? what about eTap?

No.9 might be better changing the numbered paras to i. ii. etc or tab them out. Can get a bit confusing if scrolling up and down0 -

Trivial poursuivant wrote:No.8 No SRAM? what about eTap?

Couldn't find anyone to step up for that. I covered all things mechanical and the Cycle clinic covered Shimano and Campag electronic systems. Want to volunteer?Trivial poursuivant wrote:No.9 might be better changing the numbered paras to i. ii. etc or tab them out. Can get a bit confusing if scrolling up and down

Done.seanoconn - gruagach craic!0 -

Great work, thanks Pinno. My new reference article as I can never bloody remember which limit screw is which.

Small typo - 2nd sentence of para 3. Rear mech alignment has a 'form' instead of 'from'.

Is the apostrophe thing a technical issue with a sticky thread? I only ask as 'mech' is presumably a contraction of 'mechanism' in which case an apostrophe would arguably be necessary.0 -

Joncomelately wrote:Great work, thanks Pinno. My new reference article as I can never bloody remember which limit screw is which.

Small typo - 2nd sentence of para 3. Rear mech alignment has a 'form' instead of 'from'.

I'll sort that.Joncomelately wrote:Is the apostrophe thing a technical issue with a sticky thread? I only ask as 'mech' is presumably a contraction of 'mechanism' in which case an apostrophe would arguably be necessary.

Aha, Soz Imposter, jon has a point.seanoconn - gruagach craic!0 -

The term 'mech' might be unfamiliar to some - would using the term 'gears' instead be easier for novices?FFS! Harden up and grow a pair

0

0 -

Nice job Piña, only skim read as I know everything (obviously) but looks accurate and comprehensive. Who do we know that likes SRAM and has time on his hands on occasion. So long as he doesn't mention hammers, fire or next door's garden.0

-

Svetty wrote:The term 'mech' might be unfamiliar to some - would using the term 'gears' instead be easier for novices?

I have used both nouns - 'mech' and dérailleur throughout and so, i'm sure they can work it out. However, I will add a very short sentence to remove any ambiguity.seanoconn - gruagach craic!0 -

Pinno wrote:Joncomelately wrote:Is the apostrophe thing a technical issue with a sticky thread? I only ask as 'mech' is presumably a contraction of 'mechanism' in which case an apostrophe would arguably be necessary.

Aha, Soz Imposter, jon has a point.

He has a point, but it's the wrong point. We are moving off topic slightly, but 'mechs' would be a clipped word, not a contraction. Apostrophes are used within words to show a contraction, but are not required in words like 'mech', which is a clipped form of mechanism. So the use of the apostrophe is still wrong, soz.0 -

I always wondered what the clunking noise was when I pressed the levers next to my brakes.

Grammar pedantry aside. Thanks Pinno, this is great stuff, especially for a mechanical duffer like myself. I keep meaning to properly clean and then re-cable my rear mech, and have even bought the cables, but keep putting it off. I'll have a bash at some point soon, then probably have to drive round to V68's with a b*ggered bike and see what he can do, before setting the bike on fire with fire and chucking into V68's neighbour's garden.0 -

hopkinb wrote:Grammar pedantry aside

Mainly because there's never a good time to put grammar pedantry aside:

I disagree my point was wrong. The practice of using apostrophes for clipped words as well as contractions used to be common (especially in informal settings) and I accept that a lot of people now find it obsolete. However, there is a point of view (no, not just me) that does not hold it outdated - and, as with much in language, both sides are justifiable (which is why I used the word 'arguably'). So, I don't think I'm wrong - it's just a different stance, brought up as a counterpoint to Imposter's request to 'fix' something that wasn't (in many eyes) broken.0 -

Well done. Thanks for your efforts.0

-

Joncomelately wrote:hopkinb wrote:Grammar pedantry aside

Mainly because there's never a good time to put grammar pedantry aside:

I disagree my point was wrong. The practice of using apostrophes for clipped words as well as contractions used to be common (especially in informal settings) and I accept that a lot of people now find it obsolete. However, there is a point of view (no, not just me) that does not hold it outdated - and, as with much in language, both sides are justifiable (which is why I used the word 'arguably'). So, I don't think I'm wrong - it's just a different stance, brought up as a counterpoint to Imposter's request to 'fix' something that wasn't (in many eyes) broken.

I've no idea whether it used to be commonplace or not. I don't know of the period in which it was commonplace. I didn't even know it was ever commonplace. But I do know that it has not been acceptable for the last 30 years or so, at least. If we are to accept that these forums use standard contemporary grammatical standards (that would be nice), then it is still wrong today, regardless of if or when there was ever a time that it wasn't.

But there is a certain irony in this thread opening with a line from Collins English Dictionary, and then proceeding to get basic grammar so fundamentally wrong

Anyway, back to reality...0 -

Imposter wrote:I've no idea whether it used to be commonplace or not. I don't know of the period in which it was commonplace. I didn't even know it was ever commonplace.

Sounds like an awesome and robust basis from which to attempt to be authoritarian.Imposter wrote:But I do know that it has not been acceptable for the last 30 years or so, at least.

Ah, no dice I'm afraid. See, for example, the "Concise Oxford Companion to the English Language" - which lists it as 'rare', not 'unacceptable' - or the Rothsteins' 2008 instructional, which presents it as a matter of course.Imposter wrote:If we are to accept that these forums use standard contemporary grammatical standards (that would be nice), then it is still wrong today, regardless of if or when there was ever a time that it wasn't.

Again, not quite on the money. There isn't a central, written down list of grammar rules in English - there is only a collection of expert opinions and style preferences, which often allows different ways of doing things (see, for example, starting sentences with conjunctions, or splitting infinitives. Both are allowable, but some people prefer them not to happen. A person is free to conduct their grammar in whichever way they prefer). So the apostrophe was not wrong, it just doesn't suit your personal style preference. No reason to foist that on someone else though.

Now that we've got that cleared up, we can get back to reality 0

0 -

I'm simply going by widely-accepted modern standards of journalism, rather than obscure loopholes. However, we probably both know it wasn't an attempt at clipping. We also both know that you don't need an apostrophe before a plural 'S'.

So, all things considered - would you rather leave the apostrophe in - or out?0 -

Personally, I'd probably stick it in as in my mind 'mech's' is a contraction of 'mechanisms' rather than a pluralised clipped 'mechanism', but that's just the way I look at it

. If the original title had been sans apostrophe I wouldn't have batted an eyelid mind. 0

. If the original title had been sans apostrophe I wouldn't have batted an eyelid mind. 0 -

Great work Pinno!!

Thank you!Wilier Izoard XP0 -

seanoconn - gruagach craic!0

-

Pinno wrote:Wot; no mention of grammatical style choices?!

Cheers.

FTFY0 -

Pinno wrote:Svetty wrote:The term 'mech' might be unfamiliar to some - would using the term 'gears' instead be easier for novices?

I have used both nouns - 'mech' and dérailleur throughout and so, i'm sure they can work it out. However, I will add a very short sentence to remove any ambiguity.

I meant in the thread title - partly to help beginners access the thread and partly to circumvent the grammatical 'issue'

FFS! Harden up and grow a pair

FFS! Harden up and grow a pair 0

0 -

As above, I would just change it to 'Problems with rear derailleurs' - as 'mech' may not be a familiar-enough term to newbies. Also nicely circumvents the grammatical issues.0

-

I have been informed by the mysterious Oracle who resides in a Galaxy far far away:

"...they are wrong to describe mech as a contraction as it doesn't contain the last letter so it is a shortening so doesn't require an apostrophe!"seanoconn - gruagach craic!0 -

Glad to hear it. It''s always good to second-source a correction, just to be on the safe side. Not sure about his spelling of 'apostrophel' though...

Still might just be easier to use 'derailleurs' in any case...0 -

I still disagree that it is wrong, as that suggests a near-universal standard that grammar often doesn't have. It may not be popular or to a person's taste, but that alone doesn't make it wrong.0

-

With English, usage defines the language. There is no equivalent of the French Académie française deciding what is and isn't valid usage. After all, why are we poncing around using (and mispronouncing) the French word dérailleur for a rear gear changer.0

-

“Never in the field of bike maintenance was so much pedantry dished out by so many to so few.”seanoconn - gruagach craic!0