Grease or Anti-Seize on several components.

I have a custom road bike that I have now lost enought weight to ride again.

The bike has always been well maintained and stored in a nice warm garage.

I thought it would be best to check over everything that I can do (and also use it as a learning exercise) ((I would normally go to the LBS but they are under new ownersship and the quality has dropped)).

I am also changing the chainset for a Stages one - it is the same model (Ultergra R8000 - same crank length etc) but has come with a different set of chain rings so will be changing the ones currently on the bike to the new chainset and then fitting that chain set.

I am just lost with all the Greases and products that are avalaible. I have read several websites, forums, checked manufacturer pages and rang 3 bikes shops and didn't get a coherent answer from any of them.

In short I will be checking when the Torque Wrench arrives the following, and I would be massively apprciated if someone could tell me what if anything I should use on each component.

Stem Cap 5nm

Stem Faceplate 5nm

Stem 5nm

Seat Post 2.8nm (Thompson Masterpiece) - Tech guide says "Very light coat of grease"

Seat Post Adjustment Screws 5.1nm - Tech Gudie says "Grease only bolt threads. Do not grease under bolt heador washer and do not use anti-seize".

Now on the Chainset replacement

Chainring to Chainset 12-16nm

Chainset Splines/Left Crank Arm 12 - 14nm - Tech Guide say "Premium Grease"

Question, do you put any grease where the Chainset shaft contacts the BB?

Pedals 35nm

Thank you in advance for any help

Comments

-

I use any grease that’s close to hand on things that need grease, loctite blue on anything that required loctite.

On the basis that it’s a bike, not the space shuttle.

Oh, yeah, and GT85 as chain lube.1 -

In short. If you don’t want two surfaces to seize together a light coating of grease is fine. If you get grease in between the head/washer etc and torque it up then if the grease moves you will not be at the correct torque and it may come loose.

Torque settings only apply to new bolts in clean threaded holes.

If your crank comes loose then you may damage the crank and or the spindle so double check anything you have torqued to check the torque is enough and if it’s not , torque it some more and complain to the man who produced the torque guide who will say the torque settings only apply to a new bolt in a new hole therefore they were right but you now have an old bolt in an old hole so they are now wrong 😂🤣1 -

A torque number for the stem top cap is going to be meaningless. Just nip it up with a hex key until the headset feels secure and leave it at that. Winding it up to 5nm for no good reason will probably result in something getting broken.

Mully's comments on torque settings and new bolts/threads is good advice. I'd be inclined not to use one at all - it's really not needed - but it's your choice..0 -

Generally, most bike bolts are greased.

One thing to add is when tightening multiple bolts on a component ( eg 4 bolts on a stem face plate, 2 bolts on Shimano crank arm etc) it's important to tighten them incrementally alternating between bolts. Stem face plates are best tightened in a cross pattern.1 -

So apart from a marketing perspective why do compaines sell grease and anti-seize for bikes when all above suggest grease?masjer said:Generally, most bike bolts are greased.

One thing to add is when tightening multiple bolts on a component ( eg 4 bolts on a stem face plate, 2 bolts on Shimano crank arm etc) it's important to tighten them incrementally alternating between bolts. Stem face plates are best tightened in a cross pattern.0 -

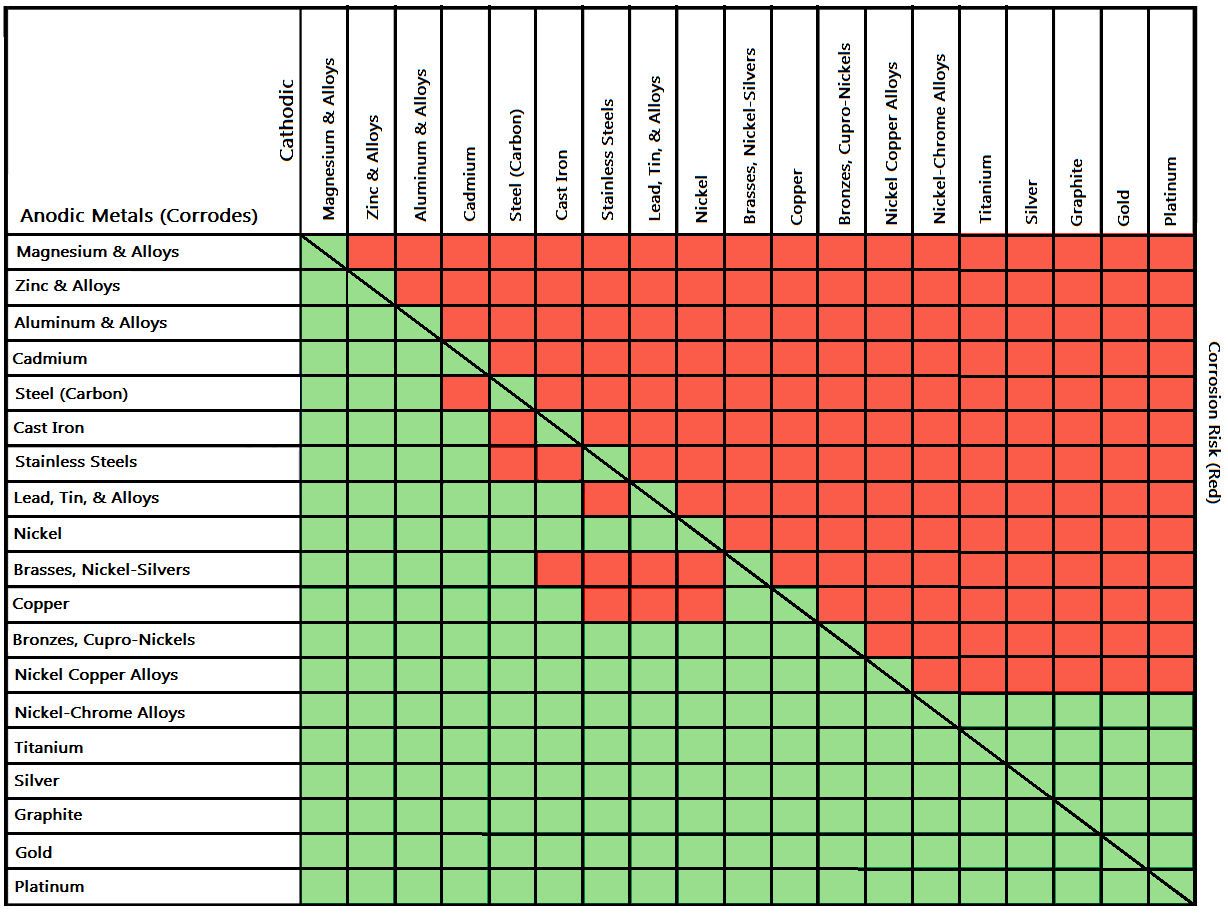

Well there's certainly a lot of marketing that goes on, but technically anti-seize is used on parts that don't move, whilst grease is used for moving parts (bearings). Anti-seize is grease with a high solids content and is often used in high temp applications. Anti-seize comes in many flavours, aluminium, copper, nickel, ptfe so choosing the correct one can be tricky. The bike industry often uses copper anti-seize, but technically this might not be correct to use with stainless bolts in aluminium threads, but I don't think anyone has ever suffered.

The other product you might see advertised is friction paste. This can be useful on seatposts or carbon handlebars. A lower torque can be used for the same clamping force.

New parts usually just have grease on the bolts, but either anti-seize or grease will stop the bolts seizing and provide a 'non dry' bolt for torquing.0 -

Great thanks. So in short apart from say the specific items like the Thompson stuff (which will be outlined in their tech docs) above and Carbon Fiber which uses specifi paste (I already use that) it doesn't really matter between grease and anti-seize but grease has less specific versions.masjer said:Well there's certainly a lot of marketing that goes on, but technically anti-seize is used on parts that don't move, whilst grease is used for moving parts (bearings). Anti-seize is grease with a high solids content and is often used in high temp applications. Anti-seize comes in many flavours, aluminium, copper, nickel, ptfe so choosing the correct one can be tricky. The bike industry often uses copper anti-seize, but technically this might not be correct to use with stainless bolts in aluminium threads, but I don't think anyone has ever suffered.

The other product you might see advertised is friction paste. This can be useful on seatposts or carbon handlebars. A lower torque can be used for the same clamping force.

New parts usually just have grease on the bolts, but either anti-seize or grease will stop the bolts seizing and provide a 'non dry' bolt for torquing.2 -

I’ve still got a big tub of anti-seize copper grease probably 30 years old left over from my former motorcycling days. I find it’s good for lightly greasing threads on parts which you will want to undo easily in the future. It’s great for things like stem bolts, cassette lock rings, chainset and ring bolts, bottle cage bolts, seat clamp bolts, bottom bracket threads, pedals etc. I also use it for seat posts and quill stems in older steel frames (carbon paste for carbon frames and seatposts). I’ve never had any components seize on any of the various frames I’ve built up so it obviously does the trick. In the old days, a light smear on the back of motorcycle brake pads stopped disc squeal. Maybe a solution for noisy road bike discs?

As for torque wrenches, I did find them useful to reduce oil leaks from things like primary chain cases on old British motorcycles, but I’ve never bothered with them for bicycles.0 -

I found that Hylomar Blue was best for jobs like that...mercia_man said:As for torque wrenches, I did find them useful to reduce oil leaks from things like primary chain cases on old British motorcycles, but I’ve never bothered with them for bicycles.

0 -

in the case of bikes, use of the correct anti-seize can help prevent galvanic corrosion where there's aluminium in contact with steel or carbon fibredavid13 said:

Great thanks. So in short apart from say the specific items like the Thompson stuff (which will be outlined in their tech docs) above and Carbon Fiber which uses specifi paste (I already use that) it doesn't really matter between grease and anti-seize but grease has less specific versions.masjer said:Well there's certainly a lot of marketing that goes on, but technically anti-seize is used on parts that don't move, whilst grease is used for moving parts (bearings). Anti-seize is grease with a high solids content and is often used in high temp applications. Anti-seize comes in many flavours, aluminium, copper, nickel, ptfe so choosing the correct one can be tricky. The bike industry often uses copper anti-seize, but technically this might not be correct to use with stainless bolts in aluminium threads, but I don't think anyone has ever suffered.

The other product you might see advertised is friction paste. This can be useful on seatposts or carbon handlebars. A lower torque can be used for the same clamping force.

New parts usually just have grease on the bolts, but either anti-seize or grease will stop the bolts seizing and provide a 'non dry' bolt for torquing.

the park tool anti-seize has the correct formulation to protect aluminium (as noted above, copper-loaded anti-seize is not really correct for aluminium)

fwiw i've had an aluminium cable stop mount eaten away by corrosion (stainless steel frame), only took a couple years, probably due to winter riding with salted roads, used anti-seize when replacing and no further problem

when aluminium corrodes, the product has higher volume than the metal, one reason people end up with jammed seat posts

as you can see, aluminium will end up losing in most cases...

my bike - faster than god's and twice as shiny0 -

https://www.bikeride.com/torque-specifications/#Headsets

This is a great guide for torque specs .

Use locktite medium on chainring bolts and rear hanger bolts ,all the rest is good waterproof grease or copperslip0