Rear Triangle Spreading - Please Help!!

Hi,

I have a first bike project on the go and need some advice!

I need to widen the rear triangles (and probably front forks) to upgrade from 6 speed to 10 speed. Please correct me if I'm wrong, but I think I need 130mm spacing for 10 speed.

What's the best way to do this? (If I'm spreading the rear triangles do i need to be worried about splitting the bridge which holds the rear brake?)

Thanks.

I have a first bike project on the go and need some advice!

I need to widen the rear triangles (and probably front forks) to upgrade from 6 speed to 10 speed. Please correct me if I'm wrong, but I think I need 130mm spacing for 10 speed.

What's the best way to do this? (If I'm spreading the rear triangles do i need to be worried about splitting the bridge which holds the rear brake?)

Thanks.

0

Comments

-

130mm is the norm for road bikes but first you have to know what material is your frame. Alu is out but if the frame is Reynolds tubing of some sort then it should be fine. I've always used Sheldon Brown's method given here:

http://www.sheldonbrown.com/frame-spacing.html

and have found this to be pretty good. Be aware that the process can be a bit nerve-racking when working with a valued frame and do ensure that you check that the frame is aligned after cold-setting.0 -

Thanks very much, It is a Reynolds steel frame. (501 I think)

I need to make 10mm and that seems quite a lot. - Have you ever had any problems with the bridge between the seat stays when cold-setting?0 -

Are you sure you need 10 mm? The old standard was 126mm so 130mm would only be 2mm each side which is nothing really. I'm unaware of any frame which would be 120mm spacing. Measure between the inside of the drop-outs if uncertain.

I've never had any problems with the bridge when doing this0 -

I've just measured it and it's 8mm I need! Which appears to defy all logic!

I'm sure we can squueze 4mm each side?!0 -

That sounds a bit odd but should be ok. Follow sb's instructions to the letter. The video is a great help. In the case of a substantial set, the faces of the dropouts will be angled i.e. not parallel, and if this is excessive then there is a frame tool that can be used to square them up and a bike shop should have this.0

-

I've got an old steel frame that needs to be spread about 3mm every time I put the wheel in, and it's fine, 8mm sounds like a lot, but is probably fine, I can't see the bridge splitting.And now you know, and knowing is half the battle

05 Spesh Enduro Expert

05 Trek 1000 Custom build

Speedily Singular Thingy0 -

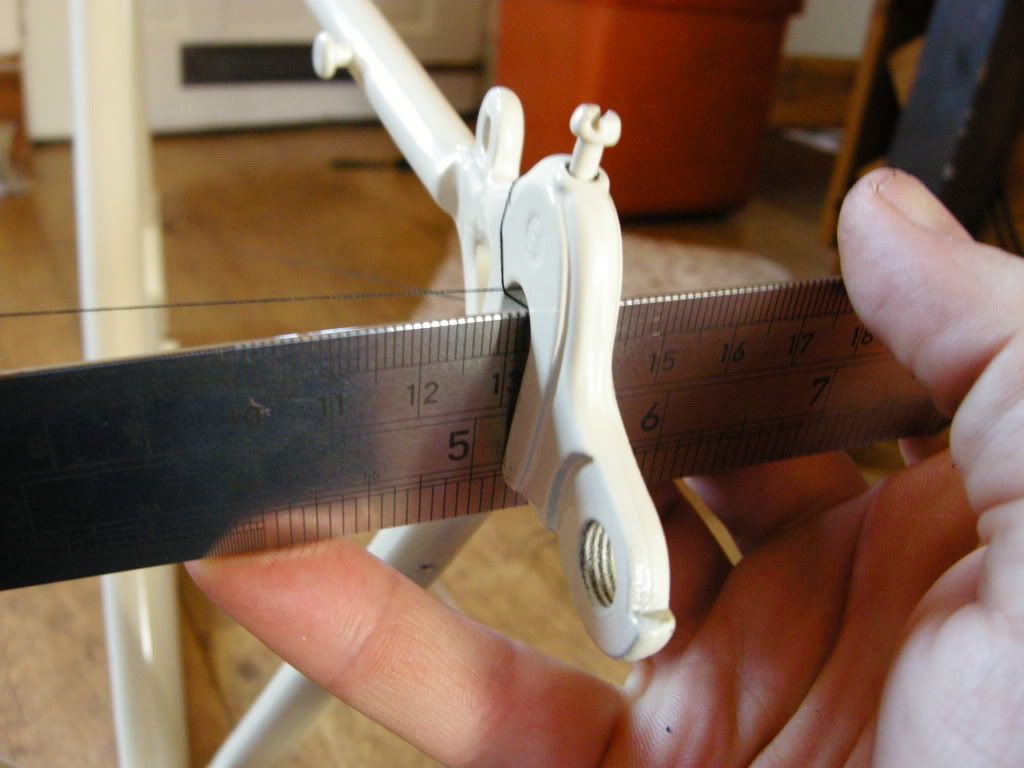

I had to spread front forks from 86mm to 100mm recently. The method I used was to buy a threaded rod, about 150mm long. Two nuts and two washers. I then put the washers and nuts on the inside of the dropouts and turned the nuts so that they moved apart. I did this a little at a time and then released everything to check how far they had spread. Bought all the bits off fleabay.

I was a bit nervous about trying Sheldon’s method. For rear forks you would obviously need a much longer threaded rod. I shouldn’t imagine that 4mm on each side of yours will warrant any problems with the brake bridge.0 -

Thanks for all your advice guys, I'll be off to buy a length of wood then!0

-

All done.

A bit of jiggling to get equal alignment on both sides of the seat post, but got it in the end.

Thanks again for the sound advice.

Rich0 -

Nice job. Good choice of wheels too. I have a set and they're fantastic.And now you know, and knowing is half the battle

05 Spesh Enduro Expert

05 Trek 1000 Custom build

Speedily Singular Thingy0 -

They're not actually the ones for my project bike, I took it off my Planet X to try it for size.

I love them but not sure if they still do them, else I'd probably get another pair!!0 -

You might find the rear mech hanger is now at a slight angle... it might work well or not... if not, don't despair and manually push it in to align it vertically with the frameleft the forum March 20230

-

ugo.santalucia wrote:You might find the rear mech hanger is now at a slight angle... it might work well or not... if not, don't despair and manually push it in to align it vertically with the frame

If you do have to do this then don't push on the RD itself. If you are confident that you have a good eye then use a large adjustable spanner to make the adjustment. If in difficulty, there is a Hanger adjustment tool which will do the job which should be held by your LBS.0